LF3015GA

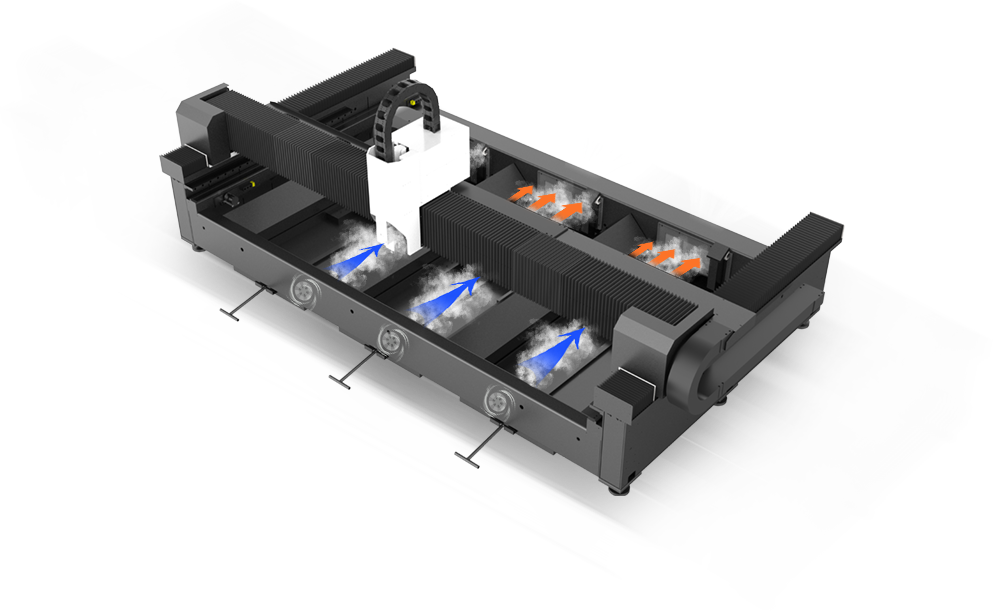

The LF3015GA model, in line with the latest technological advancements, further enhances its user experience with an intuitive control panel, allowing operators to easily navigate through the machine's functions. The outward moving table is designed for efficiency, significantly reducing the time taken for the loading and unloading process of metal plates.

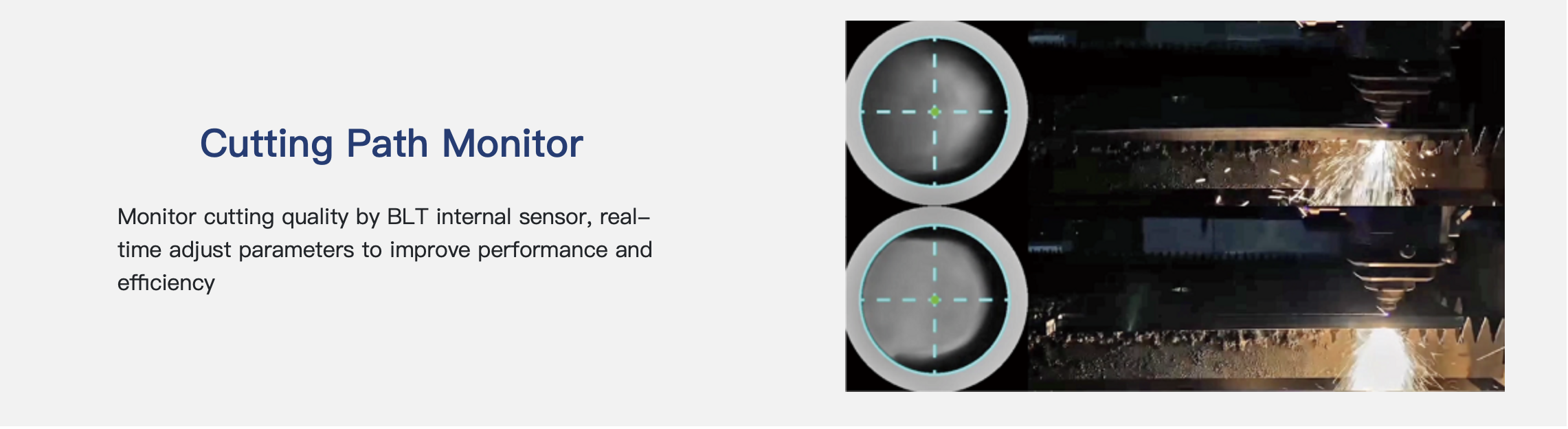

The integrated cameras serve a dual purpose. Firstly, they allow for real-time monitoring of the machine's operations, ensuring that any potential issues can be identified and rectified promptly. Secondly, they enable the precise tracking of the cutting process, ensuring a high level of accuracy and quality control.

The machine's external display is a distinct feature that provides clear and detailed visualization of the machine's operations, enabling operators to monitor and control the processes effectively.

Lastly, the inclusion of drawers for capturing separate parts during the cutting process shows the thoughtful design in managing waste and increasing work efficiency.These drawers not only keep the workspace clean but also make it easier to sort and recycle the cut-offs.

Together, these features make the LF3015GA model an optimal choice for those seeking a combination of safety, quality, and efficiency in their metalworking processes.

- The LF3015GA model have wide range for sheet metal cutting for size and thickness,Sheet metal: Size 1500mm - 3000mm ,Thinness: (0.5mm Up to 25mm ).

- The LF3015GA model is a powerful tool in metal processing. It is specifically designed to handle a variety of metals, such as flexible iron sheets, stainless steel, aluminum, copper, and brass. Its high-speed operations do not compromise on efficiency, ensuring that each cut is clean and precise.

- The model's versatility sets it apart in the market. Whether it's the sturdy stainless steel, the lightweight aluminum, the conductive copper, or the corrosion-resistant brass, The Xemac-300FC model processes each material with equal ease and precision.Its high-speed cutting capabilities not only increase productivity but also reduce downtime, making it an ideal choice for businesses that value time and efficiency.

- The high efficiency of The LF3015GA also means less waste material, contributing to a more sustainable and cost-effective operation.Furthermore, The LF3015GA model is built with durability in mind. It's designed to withstand the rigors of heavy-duty cutting tasks, ensuring a long operational life and providing a reliable solution for all your metal cutting needs.

Working Size | |

X AXIS | 1500 mm |

| Y AXIS | 3000 mm |

Maximum Speed | ||

XY Speed | 140 | mm/min |

MAXIMUM WORKPIECE WEIGHT |

1050 kg |

LASER POWER 3000 W | ||

Model | 3000 | W |

| Max Thickness | 20 mm | Mild steel |

| 12 mm | STAINLESS STEEL | |

| 12 mm | ALUMINIUM | |

| 5 mm | COPPER | |

| 5 mm | BRASS | |

LASER POWER 6000 W | ||

Model | 6000 | W |

| Max Thickness | 25 mm | Mild steel |

| 20 mm | STAINLESS STEEL | |

| 15 mm | ALUMINIUM | |

| 10 mm | COPPER | |

| 10 mm | BRASS | |

LASER POWER 12000 W | ||

Model | 12000 | W |

| Max Thickness | 30 mm | Mild steel |

| 25 mm | STAINLESS STEEL | |

| 25 mm | ALUMINIUM | |

| 12 mm | COPPER | |

| 12 mm | BRASS | |

CONTROLLER & SOFTWARE

HypCut is custom software developed for high power laser cutting. Professional high-power laser cutting process is provided, realizing intelligent production. It supports planning and scheduling to assist production management; Its modular design provides users with more concise and efficient operations and helps users complete production quickly.